Week Two

Click the Arrow to Proceed to Project Page

Click the Arrow to Proceed to Project Page

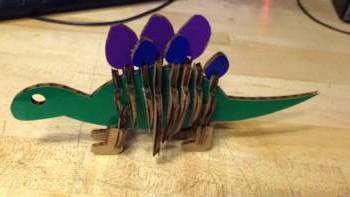

Build-Your-Own Dinosaur

The concept: By combining two-dimensional pieces using press-fits, I wanted to create a psuedo-three-dimensional model. In order to do this, I attempted to model a cartoon-like skeleton of a stegosaurus.

Method:

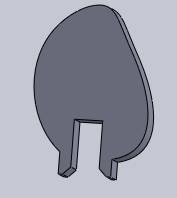

I used SolidWorks to design the dinosaur. By extruding the body piece to the thickness of the cardboard, I was able to effectively match the "peg" to the "slot" that I created in the ribs. In order to ensure that the press-fit would be tight, I made sure that the slot was smaller than the peg. To do so systematically, I used the following formula:

peg = slot - 2(kerf) - overlap. Based on some research, kerf is essentially the width of the cut made by the laser (even though the lines are set to be hairlines, the laser inherently produces cuts of some width). For my purposes, I assumed that this would be about .007". The overlap would vary depending on the material, so for this instance, I assume an overlap of about .006. For stiffer materials, I would use a lower overlap value. Cardboard is extremely forgiving, so a greater amount of overlap could be used.

Key issues:

If pieces were made to be too small, two issues arose. The first was that some pieces burned on one side, which diminished their ability to hold a tight fit. I initially forgot to change the frequency of the laser down to 700, which called the cardboard to burn. After that experience, I often erred on the side of making the power, speed, and frequency of the laser too low. This made it hard to remove the pieces from the cardboard, as they were not cut all the way through. I ended up using a box cutter to punch out some of the pieces. I also discovered that the carboard did not have a consistent thickness, and as it was cut, the cardboard did not lie flat uniformly on the bed. This attributed to some of my issues with cutting all the way through. Finally, I discovered that if pieces are too small, the carboard was flexible and flimsy enough that the piece would break when I attempted to add it to the assembly.

As the final component for my project this week, I sent the same .dwg files to the vinyl cutter to color my dinosaur.